Product

Overview

The HY150T-C diesel engine water pump unit is an efficient power drainage equipment developed by Huangshan Zhongguangtai Special Equipment Co., Ltd. (a member of the China Fire Protection Association, a high-tech enterprise, and has passed ISO9001 quality system certification). It is powered by a diesel engine and integrates features such as high reliability, stable operation, and long service life. It is widely used in urban flood prevention and drainage, emergency fire protection, landscaping sprinkling, industrial water supply, and agricultural irrigation, providing efficient solutions for various liquid transportation scenarios.

"Core Design and Performance Features

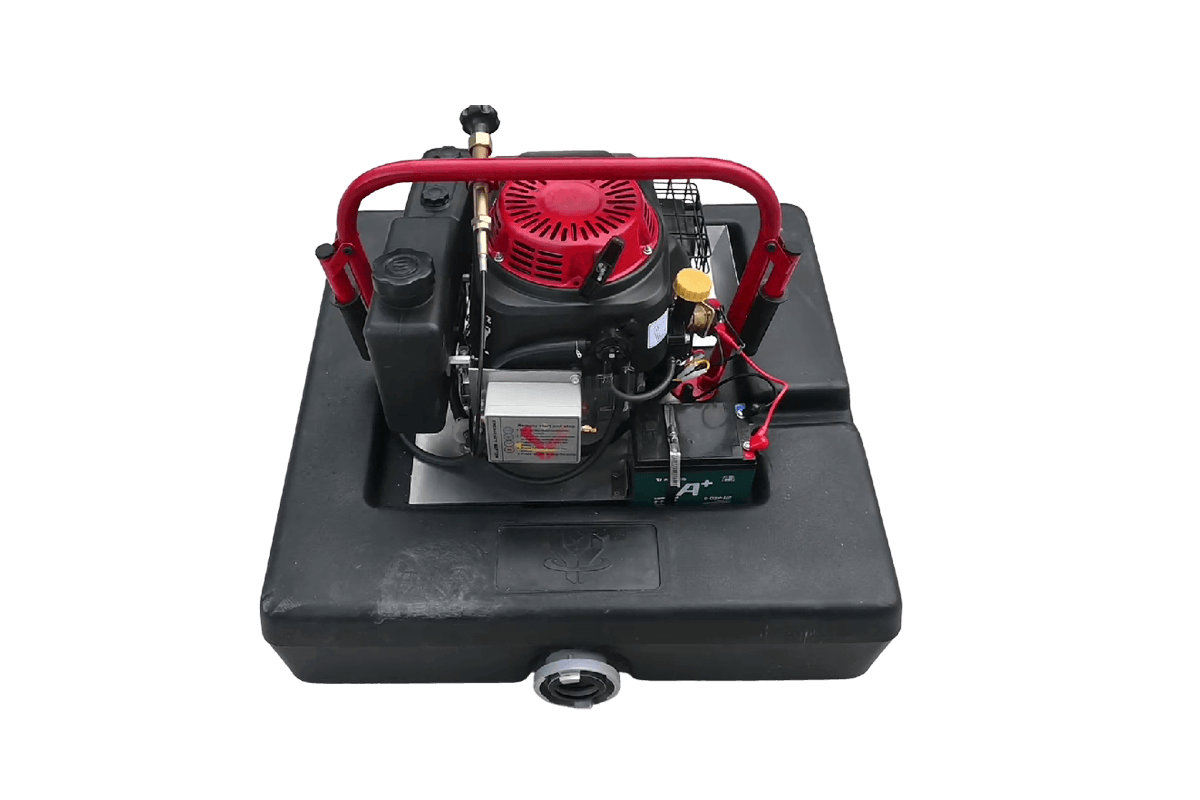

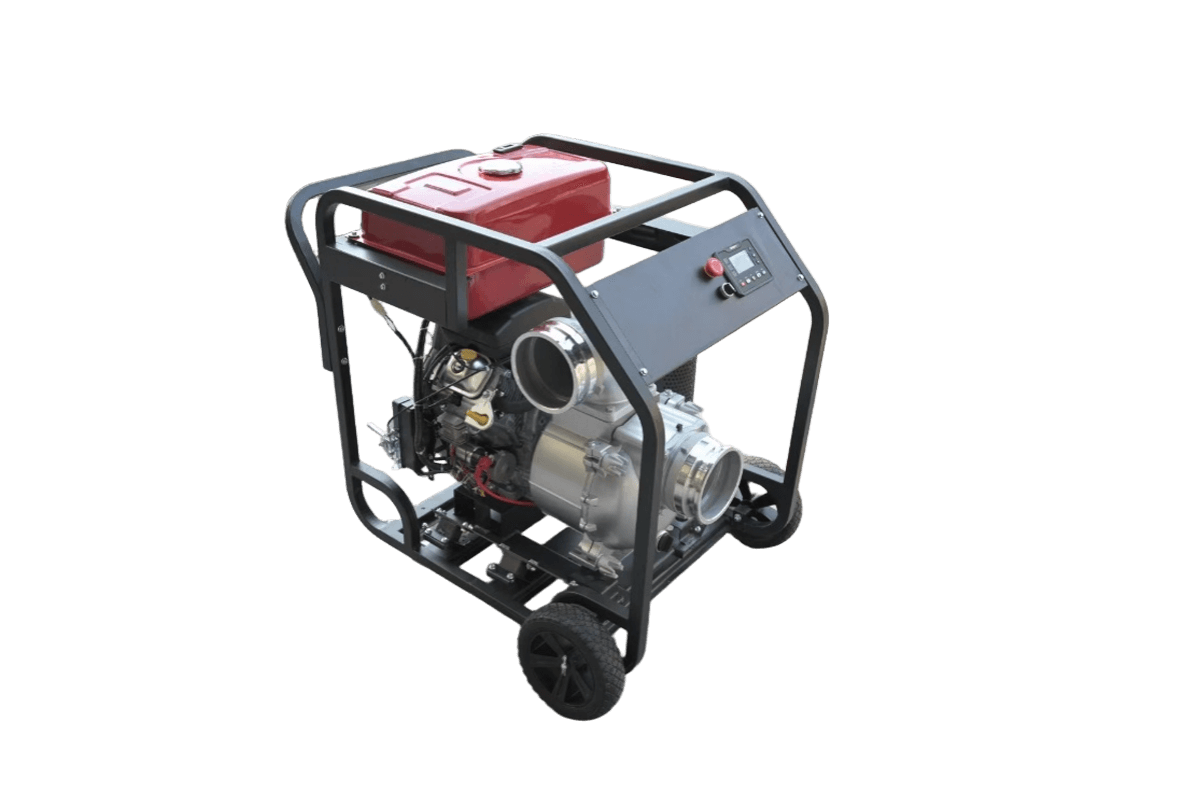

This unit is a self-priming centrifugal pump (single-stage suction type), using a national standard hydraulic model. It has a simple structure and high operating efficiency, featuring high rotational speed, small size, light weight, and convenient operation and maintenance. The overall composition includes a dual-cylinder four-stroke air-cooled diesel engine, self-priming centrifugal pump, control system, and connecting pipelines. The power transmission is efficient, enabling rapid water extraction and pumping.

Power Core: Equipped with a high-performance dual-cylinder four-stroke air-cooled diesel engine, with a maximum input power of 15kW. It supports manual start and electric start, uses non-contact transistor ignition, has a fuel tank capacity of 20L, and a wind-cooling design. The power is strong, fuel-efficient, environmentally friendly, and has a low failure rate.

Pump Performance: The pump body is made of thickened aluminum alloy, wear-resistant and corrosion-resistant; the impeller is made of cast iron wear-resistant material, with strong flow capacity. The maximum flow rate is 160m³/h, the maximum head is 23m, and both the inlet and outlet are 150mm large-diameter. It has strong adaptability. The self-priming ability is outstanding, with a maximum self-priming height of 8m, and the self-priming time is only 90s when it is completed. The inlet has a coarse grille-style stainless steel filter screen, which can filter particles with a maximum diameter of 38mm, and has excellent anti-blocking performance."

"Intelligent Control and Operational Convenience

The integrated control panel of the unit integrates function buttons for engine start-stop, throttle adjustment, and pump operation control, enabling one-stop operation and simplifying the operation process. It is equipped with a liquid crystal integrated monitoring display screen that can clearly display key parameters such as working pressure, rotational speed, cylinder temperature, and cumulative usage time in real time. The backlight can be adjusted to facilitate the operators' real-time grasp of the working conditions and timely adjustments.

Supporting Equipment and Adaptability

Inlet and outlet water hoses: The suction hose has a diameter of 150mm and a length of 8m. It uses a reinforced plastic pipe that can withstand a negative pressure of 1.0MPa without deformation. One end is equipped with a filter screen, and the other end is equipped with a quick connector and fastening device. The outlet pipe (water hose) has a diameter of 150mm and a total length of 100m (20m per unit), made of high-strength polyurethane material, with a high-strength fiber woven layer inside, with a pressure resistance of 0.6MPa. Both ends are equipped with quick connectors, facilitating splicing extension and connection with other facilities, meeting the requirements for long-distance efficient drainage.

Mobility and Maintenance: It is equipped with a steel frame structure and mobile wheels with braking stop devices, making it convenient to move. It includes a regular maintenance tool kit, facilitating on-site maintenance.

Relying on Zhongguantai's professional R&D and manufacturing capabilities and lifelong service system, the HY150T-C diesel engine water pump unit has ""efficiency, reliability, and flexibility"" as its core advantages, providing stable support for various drainage and liquid transportation scenarios, and helping to improve operation efficiency and emergency response speed."

|

number |

Equipment Name |

Specification parameter |

Quantity |

|

|

1 |

Engine |

Type |

Two-cylinder four-stroke air-cooled diesel engine |

One unit |

|

Starting methods |

Manual start, electric start |

1 group |

||

|

Fuel tank |

Volume: 20L |

1 unit |

||

|

2 |

Centrifugal pump |

Type |

Self-priming centrifugal pump |

One unit |

|

Impeller |

Wear-resistant cast iron material |

1 unit |

||

|

Pump body |

Made of aluminum alloy material |

1 unit |

||

|

Sealing device |

Packing seal and mechanical seal |

1 set |

||

|

Bearings |

Copper alloy, wear-resistant coating |

1 group |

||

|

3 |

Frame and mobile wheels |

Frame made of steel tubes; mobile wheels with braking stop device |

1 set |

|

|

4 |

Water pipe |

Suction hose |

Can withstand negative pressure of 1.0 MPa without deformation, 8 meters per unit |

8m |

|

Water hose |

Can withstand pressure of 0.6 MPa, 20 meters per unit, equipped with clamps, etc. |

100m |

||

|

5 |

Maintenance toolkit |

Conventional |

1 set |

|

Customized now

Customized now