Product

Overview

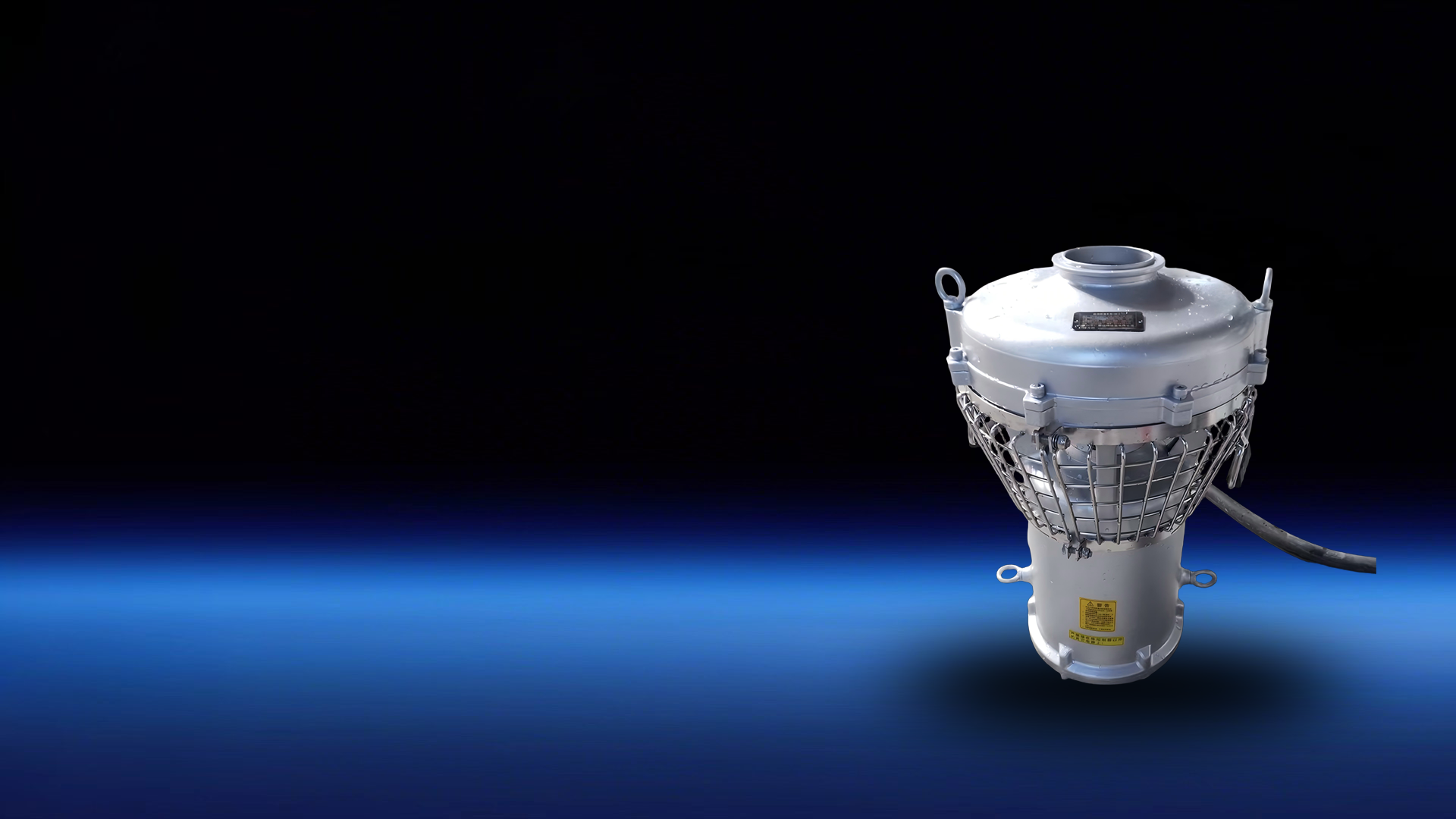

"The 100m3/h, 100-meter-head submersible water pump is a high-head drainage equipment developed by Huangshan Zhongguangtai Special Equipment Co., Ltd. (a member of the China Fire Protection Association, a high-tech enterprise, and has passed ISO9001 quality system certification). It is specifically designed for high-head drainage scenarios and is widely used in flood control, fire protection, water conservancy, power, municipal pipelines, geological and marine exploration, etc. It can effectively meet the needs of deep well drainage and high-altitude drainage, providing strong support for disaster prevention, mitigation and relief efforts.

This submersible water pump has a rated flow of 100m3/h and a rated head of 100m. When the flow is 100m3/h, the head remains stable at 100m. Its rated power is 50kW, the rated voltage is 380V, the specified rotational speed is 3300r/min, and the electric pump efficiency is ≥60.00%. It has efficient drainage capabilities.

In terms of performance, the submersible pump uses a permanent magnet synchronous motor, with an insulation class of F and a protection level of IP68. It can operate safely and stably underwater. The insulation resistance at both cold and hot states is ≥500MQ, capable of withstanding harsh electrical environments. The electric pump can pass through 25mm solid particles and adapt to complex water quality. At the same time, it is equipped with a reliable grounding device and a clear grounding mark, with leakage protection function. In the event of leakage, it can automatically cut off the power supply. It also has automatic alarm functions for overvoltage, undervoltage, overcurrent, phase loss, short circuit, overheating, etc. For recoverable faults, it supports automatic or manual deletion to restore normal operation."

"The pump body is made of wear-resistant and corrosion-resistant lightweight high-strength alloy material. The hydraulic components (impeller, impeller chamber, and diffuser) are integrally formed of wear-resistant and corrosion-resistant stainless steel. The pump shaft is made of 2Cr13 steel, the impeller is made of stainless steel, with a Vickers hardness (HV) of ≥1000 degrees, ensuring the durability and anti-wear ability of the equipment. The inlet filter screen of the submersible pump is made of 304 stainless steel, which is easy to disassemble and clean. The weight of a single pump is ≤70kg, with a size of (350mm in diameter * 675mm in height) + 5%, facilitating transportation and installation. Each pump is equipped with 10m submersible cable, with a cable sheath, and uses an IP67 waterproof connector between the cables.

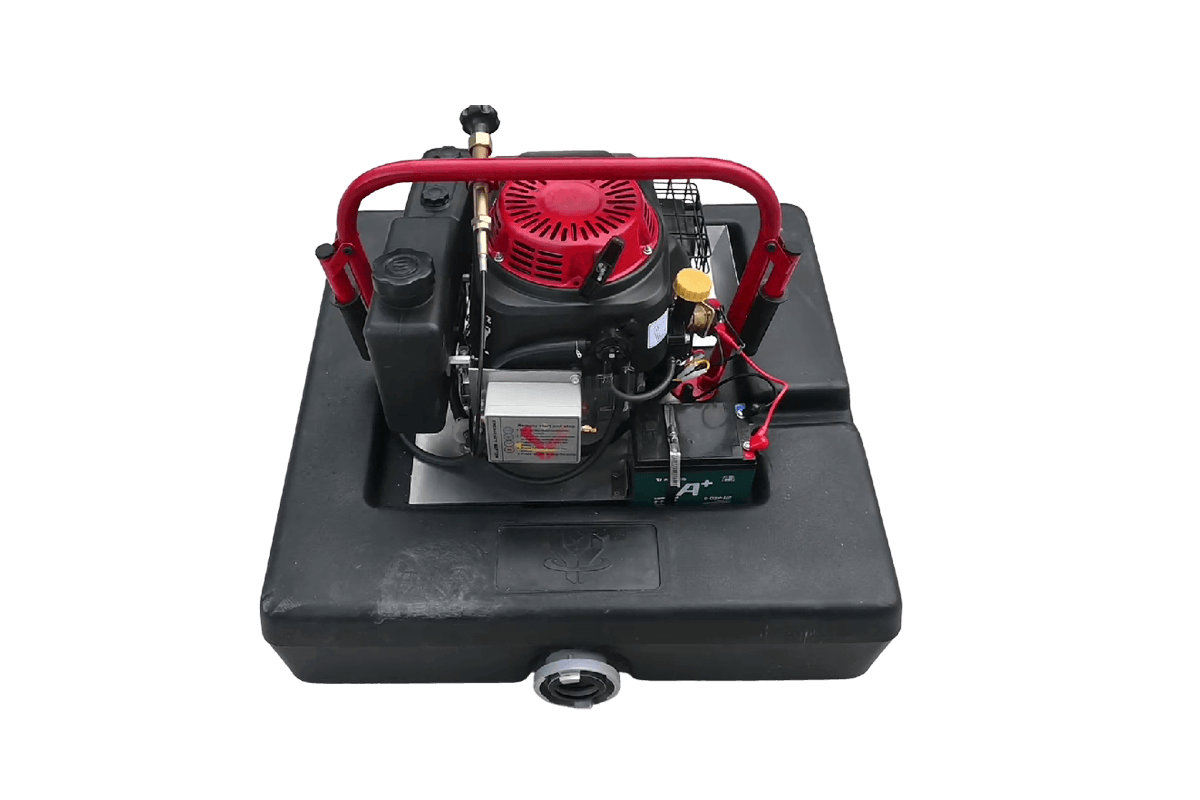

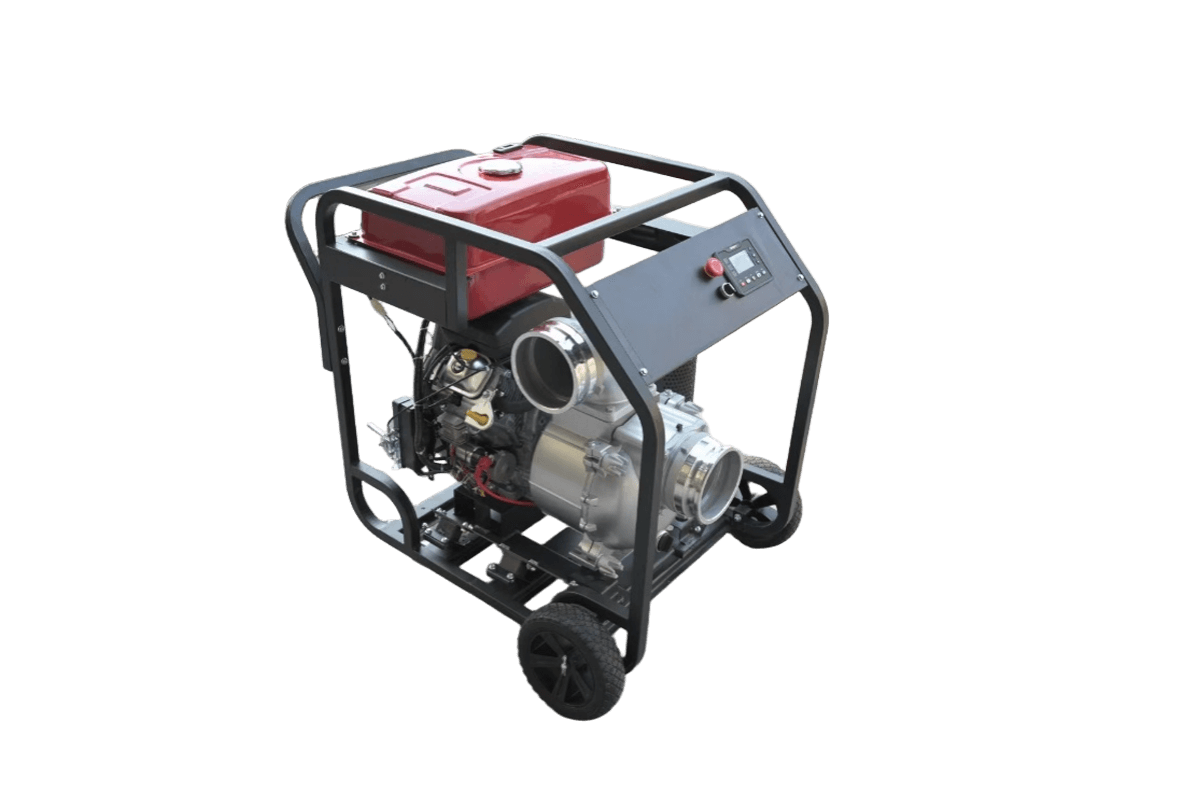

The control system adopts an intelligent control cabinet, with an integrated design. The material is cold-rolled steel with a thickness of ≥1.5mm, weighing 40kg ± 5%, with a protection level of IP55, suitable for outdoor rain protection. The control methods include one-to-one and one-to-two control of the water pump, with each pump equipped with a separate control system, supporting one-click start, without the need for debugging. The control cabinet comes with an invisible handle and a detachable protective base, facilitating disassembly, transportation and maintenance. The interior adopts advanced control circuits and intelligent control systems, capable of fully controlling the submersible water pump. Through the control panel, it can conveniently start, stop, adjust operating parameters, and has soft start and soft stop functions. At the same time, an external power socket is provided to meet the power requirements of other electrical equipment, and there is an electrical leakage protection device and IP67 protection level quick plug, with overloading, short circuit, and leakage protection functions, capable of real-time monitoring of the pump's operating status (motor temperature, current, voltage, flow rate, head, etc.), and alarming and taking protective measures in case of abnormalities. The power supply drive mode supports diesel generator or mains power."

"The special water hose is made of polyester filament polyurethane material (outer layer of polyester filament, inner lining of polyurethane), with a coating of wear-resistant and waterproof resin, and the lining thickness is 0.73mm. The woven fabric layer of the hose is evenly woven, the surface is clean, there are no skipped double threads, broken double threads, skipped weaves or scratches, and the unit length weight is 1145g/m ± 5g/m. The specification is a diameter of DN100 (100mm), inner diameter size of 100 ± 5mm, minimum working pressure of 0.9 ± 0.1MPa, minimum burst pressure of 3.2 ± 0.5MPa, elongation rate of 3.4%, expansion rate of 2.6%, and adhesion strength of 45N/25mm ± 5N/25mm. The single length is 20m, and each pump is equipped with 1 single hose, with a stainless steel quick connector and a stainless steel clamp with a butterfly nut tightening device. It has the characteristics of wear resistance and puncture resistance, foldable rolling, no sticking phenomenon, etc. There is no leakage or rupture under a pressure of 2.4kg.

The cable specification is (3×25 + 1×10) mm², made of national standard copper core material, as JHS grade waterproof cable (diving grade). It is led out from the submersible pump, equipped with a steel-made cable sheath integrated with the pump, and the interfaces are connected with IP67 quick waterproof connectors, with a standard length of 20m, and the interface protection level is IP67."

"The float ring is made of high-strength polyurethane and is formed through a one-piece foaming process. It can meet the buoyancy requirements during the operation of the submersible water pump. Even if it is damaged, it will not affect normal use. It is equipped with a snap ring and a soft fixed lifting rope for connection. The standard soft fixed lifting rope is 10 meters long. In addition, a maintenance tool kit is also provided, which contains common tools such as wrenches and screwdrivers, making it convenient for on-site maintenance and repair.

With its professional production, research and development, manufacturing capabilities, strict quality inspection, and complete after-sales service system, Zhongguantai provides a one-stop service for this submersible water pump, from purchase, personalized customization to after-sales, ensuring that the product can operate safely, reliably and efficiently in various high-head drainage scenarios, and contribute to disaster prevention, mitigation and relief efforts."

|

Equipment Name |

Quantity |

Remark |

|

High-head submersible pump |

1 unit |

Flow rate: 100 cubic meters per hour, Head: 100 meters |

|

Control system |

1 set |

Including control cabinet and control software |

|

Cable |

20 meters |

National standard copper core with IP67 quick connector |

|

Water hose |

20 meters |

DN150; 20 meters per piece, with stainless steel quick connector |

|

Floating ring |

1 unit |

Single pump equipped with 1 float ring |

|

Maintenance tool kit |

1 set |

/ |

Customized now

Customized now